Cacao: A Captivating Experience with Addictive Brown Beans

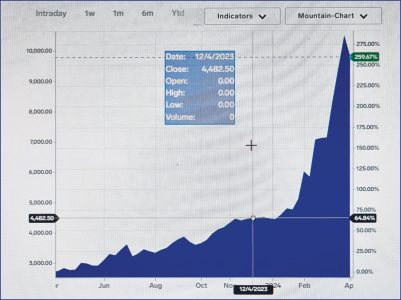

I couldn’t believe it, but there was the headline on the local news, the price of cacao had surpassed $10,000 per metric ton on the international commodities market. Could that be possible? When in doubt “Google it”. I did, and the close for that day, April 2, 2024, was $10,051 per ton. When I began planting cacao in 1979 the international price of the fascinating, addictive, aromatic beans, was around $3000 a ton, seven years later, during the course of one year, it plunged to $700. Our cost of harvesting and processing was more than that. We quit spending money on the plantations and returned them to Mother Nature. We abandoned those years of learning and the hard work of producing and processing those beans that were once considered to be so valuable that they were used as currency.

I couldn’t believe it, but there was the headline on the local news, the price of cacao had surpassed $10,000 per metric ton on the international commodities market. Could that be possible? When in doubt “Google it”. I did, and the close for that day, April 2, 2024, was $10,051 per ton. When I began planting cacao in 1979 the international price of the fascinating, addictive, aromatic beans, was around $3000 a ton, seven years later, during the course of one year, it plunged to $700. Our cost of harvesting and processing was more than that. We quit spending money on the plantations and returned them to Mother Nature. We abandoned those years of learning and the hard work of producing and processing those beans that were once considered to be so valuable that they were used as currency.

On a recent trip to Guatemala, I visited a shop that sold many different types of cacao from dry, toasted beans to fancy chocolate. Among other goodies, I bought a packet of beans, which reminded me of the days when we cultivated cacao at Hacienda Barú.

In 1979 and 1980 we planted about 12 hectares of cacao, one of the few crops that require zero chemicals. You can use chemicals, but the end product is tastier and less costly to produce without them. Quality depends on growing, harvesting, and processing methods. The variety of cacao has very little to do with the tastiness of the final product.

The right amount of shade is important, and the plants you use to provide that shade can eliminate the need for chemical fertilizer. We started the cacao plants in plastic bags filled with organic soil in a nursery and later moved them to the area that would become the plantation. The small cacao plants were spaced three meters apart and surrounded by four pigeon pea plants. Pigeon peas are legumes whose roots fix nitrogen in the soil, thus eliminating the need for it in chemical form. These grew much faster than the cacao and provided shade for the young plants for the first three years. Then the pigeon peas finished their life cycle and died, and we cut them down. Pigeon peas are good to eat, but most Costa Ricans don’t know what they are, and there is no market for them. One day a representative from the United Nations Refuge program came to see me. Not far from Hacienda Barú there was a UN refugee camp for people fleeing the civil war going on in Nicaragua at that time. When he found that we had no plans to harvest the pigeon peas he asked if we would donate them to the camp. I agreed, and he brought a truckload of refugees to do the picking and took away a truckload of pigeon peas with happy refugees sitting on top of the sacks.

The right amount of shade is important, and the plants you use to provide that shade can eliminate the need for chemical fertilizer. We started the cacao plants in plastic bags filled with organic soil in a nursery and later moved them to the area that would become the plantation. The small cacao plants were spaced three meters apart and surrounded by four pigeon pea plants. Pigeon peas are legumes whose roots fix nitrogen in the soil, thus eliminating the need for it in chemical form. These grew much faster than the cacao and provided shade for the young plants for the first three years. Then the pigeon peas finished their life cycle and died, and we cut them down. Pigeon peas are good to eat, but most Costa Ricans don’t know what they are, and there is no market for them. One day a representative from the United Nations Refuge program came to see me. Not far from Hacienda Barú there was a UN refugee camp for people fleeing the civil war going on in Nicaragua at that time. When he found that we had no plans to harvest the pigeon peas he asked if we would donate them to the camp. I agreed, and he brought a truckload of refugees to do the picking and took away a truckload of pigeon peas with happy refugees sitting on top of the sacks.

At the same time, when we planted cacao seedlings and pigeon peas, we planted cuttings that would take root and grow into large leguminous trees called poró. Poró trees are fast growing and need to be pruned often. The branches and leaves from each pruning contained enough nitrogen to nurture the cacao trees indefinitely. In addition to nitrogen, the pruned debris decomposed and provided organic material that enriched the soil with a multitude of nutrients and bulky fiber. It was a lot like compost.

Once a chicken farmer called me saying that he had a huge pile of chicken manure that he would give me if I would haul it away. I checked with the agricultural department and was told that chicken manure was the best fertilizer I could use. The chicken farmer bagged it in used chicken feed bags, and I hired a large truck to bring it to Hacienda Barú. From the day we unloaded the truck, some of the workers complained about the chicken manure, saying it was unhealthy and would make them sick. One of them even went to the health department and filed a formal complaint against Hacienda Barú. They told him we hadn’t broken any laws or rules and, to the contrary, they were happy to hear we were practicing organic agriculture. Everywhere he went to complain he got pretty much the same answer. Finally, he gave up. About a year later the agricultural department came by and took a dozen or so soil samples at various locations within the plantation. They tested the samples and later gave us a certificate saying that the plantation was chemical-free. At that time organically produced crops didn’t earn much of a premium, but there was one cacao buyer who gave a little higher price for the chemical-free product. It didn’t cost any more to go the organic route, and I don’t understand why more farmers didn’t do it.

Once a chicken farmer called me saying that he had a huge pile of chicken manure that he would give me if I would haul it away. I checked with the agricultural department and was told that chicken manure was the best fertilizer I could use. The chicken farmer bagged it in used chicken feed bags, and I hired a large truck to bring it to Hacienda Barú. From the day we unloaded the truck, some of the workers complained about the chicken manure, saying it was unhealthy and would make them sick. One of them even went to the health department and filed a formal complaint against Hacienda Barú. They told him we hadn’t broken any laws or rules and, to the contrary, they were happy to hear we were practicing organic agriculture. Everywhere he went to complain he got pretty much the same answer. Finally, he gave up. About a year later the agricultural department came by and took a dozen or so soil samples at various locations within the plantation. They tested the samples and later gave us a certificate saying that the plantation was chemical-free. At that time organically produced crops didn’t earn much of a premium, but there was one cacao buyer who gave a little higher price for the chemical-free product. It didn’t cost any more to go the organic route, and I don’t understand why more farmers didn’t do it.

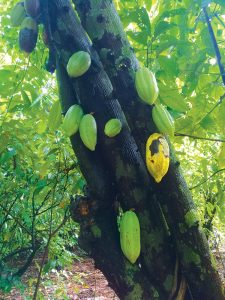

Harvesting and processing were the most important steps in assuring a high-quality product, one that had an aroma that immediately brought an image of a steaming cup of hot cocoa to mind. The mature pods were orange-colored. The green ones and the dark red ones weren’t ready to be harvested. Once cut off the tree the ripe pods were opened with a machete exposing the seeds and a sweet and sour syrup that coated them. It was all dumped in buckets and hauled to the fermenting bins. The raw beans were dumped into the top bin and every two days moved to the next one just below it. Moving them allowed air into the mixture which was an essential part of the process. There were holes in the bottom of the fermentation bins so the alcohol, a by-product, could drain off. A friend of mine always came around when we were fermenting the cacao to capture the ethanol-laden juice from which he made wine. After three bin changes, about six days, the beans were dark brown and ready for drying.

We built drying racks we could roll out when it was sunny and roll back under a roof when it looked like rain. Three days of good hot sun were necessary to dry the beans to the level required by the buyers, 7% moisture. At this stage, everyone who worked with the cacao got in the habit of occasionally grabbing a bean, cracking the outer shell, and eating the dark center which was pure bitter cacao. In other words, they became addicted. Even the neighbor’s chickens became addicts. I am a cacao (chocolate) addict to this day.

We built drying racks we could roll out when it was sunny and roll back under a roof when it looked like rain. Three days of good hot sun were necessary to dry the beans to the level required by the buyers, 7% moisture. At this stage, everyone who worked with the cacao got in the habit of occasionally grabbing a bean, cracking the outer shell, and eating the dark center which was pure bitter cacao. In other words, they became addicted. Even the neighbor’s chickens became addicts. I am a cacao (chocolate) addict to this day.

By the third year, the cacao plants had grown into small trees that produced a few cacao pods, our first harvest. At five or six years the trees reached full production. After a couple of profitable years, the bottom fell out of the market, so we gave the plantations to the monkeys. Today those old plantations are one of the most biodiverse habitats on Hacienda Barú National Wildlife Refuge. But all that is another story. See my first book Monkeys Are Made of Chocolate.

There is much more to the story of cacao than the experience related above. If you are interested in seeing and learning the fascinating story of the origin, early usage, and current methods of processing cacao beans, there is a tour available that tells it all. Learn about it at: costaricanchocolate.com

Jack Ewing was born and educated in Colorado. In 1970 he and his wife Diane moved to the jungles of Costa Rica where they raised two children, Natalie and Chris. A newfound fascination with the rainforest was responsible for his transformation from cattle rancher into environmentalist and naturalist. His many years of living in the rainforest have rendered a multitude of personal experiences, many of which are recounted in his published collections of essays, Monkeys are Made of Chocolate & Where Jaguars & Tapirs Once Roamed. His latest book is, Monkeys are Made of Mangos.